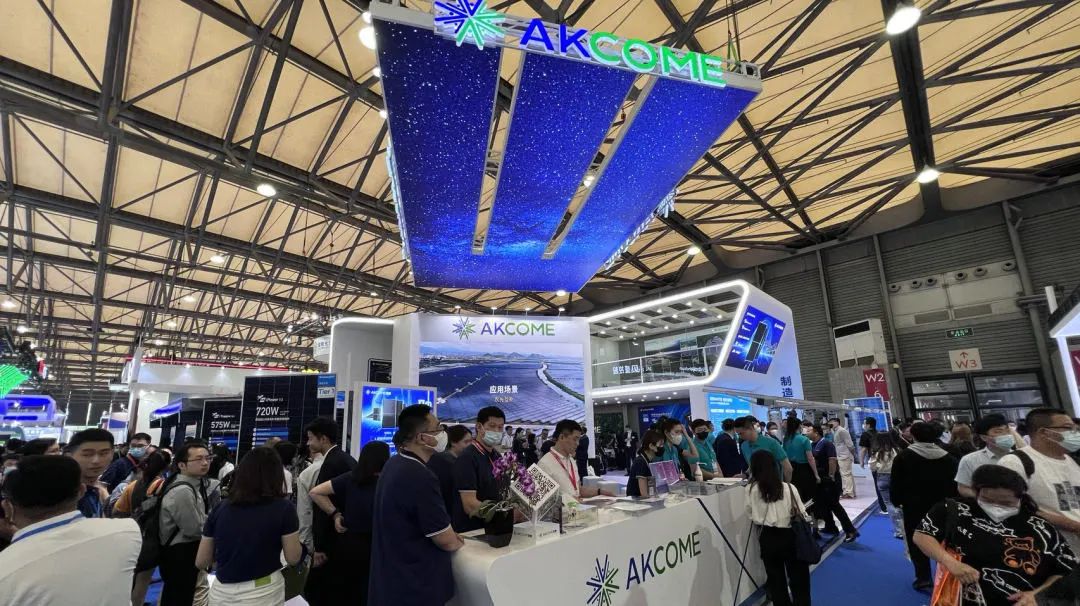

The largest and most global professional SNEC(2023) International Photovoltaic Power Generation and Smart Energy Conference & Exhibition was perfectly closed on May 26. At this exhibition, Akcome presented the up-to-date research achievements and product applications with N-type heterojunction (HJT) and TOPCon, unveiling forward-looking layout and brand strength of Akcome in the field of N-type technology in all aspects, and providing refreshing ideas for promoting global N-type technology transformation and commercial applications.

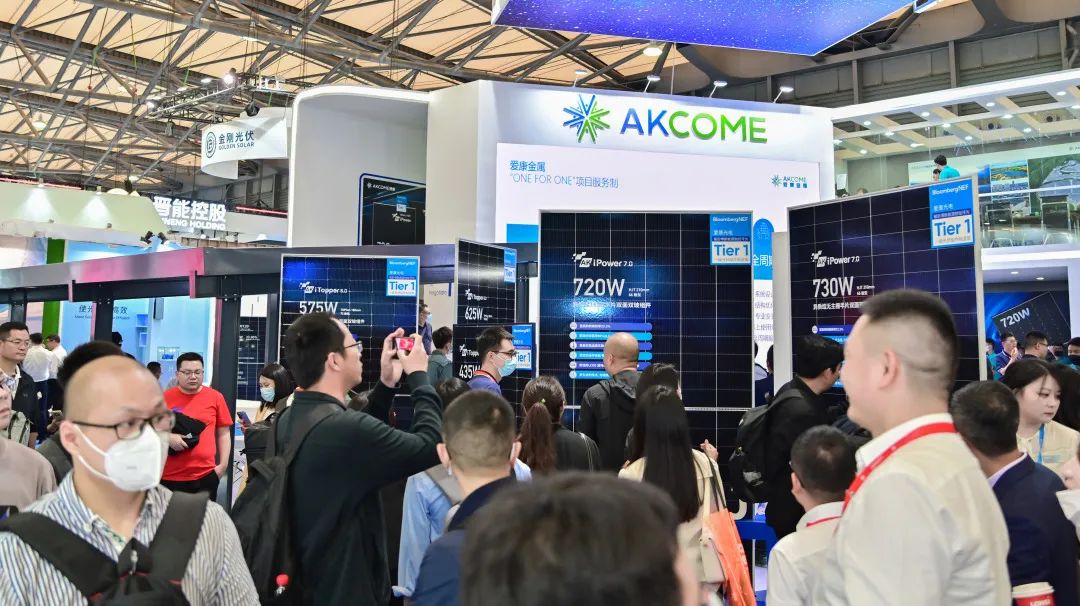

With the industries' demand for lower cost, high efficiency, and high reliability in photovoltaic power generation, the masses gradually shift their concerns to N-type photovoltaic technology. N-type technology products integrated with peak performance and excellent experience combine leading strengths involving high conversion efficiency, high bifaciality, low temperature coefficient and long lifecycle, and supports bringing users ultra-high full lifecycle power generation and economic benefits. At the exhibition, Akcome showed innovative achievements on the basis of the state-of-the-art N-type core technology: AK iPower 7.0 Series HJT high-efficiency modules and AK iTopper 4.0/5.0/6.0 Series TOPCon modules, contributing to the energy system transformation and leading the industry's N-type technology trend in the future.

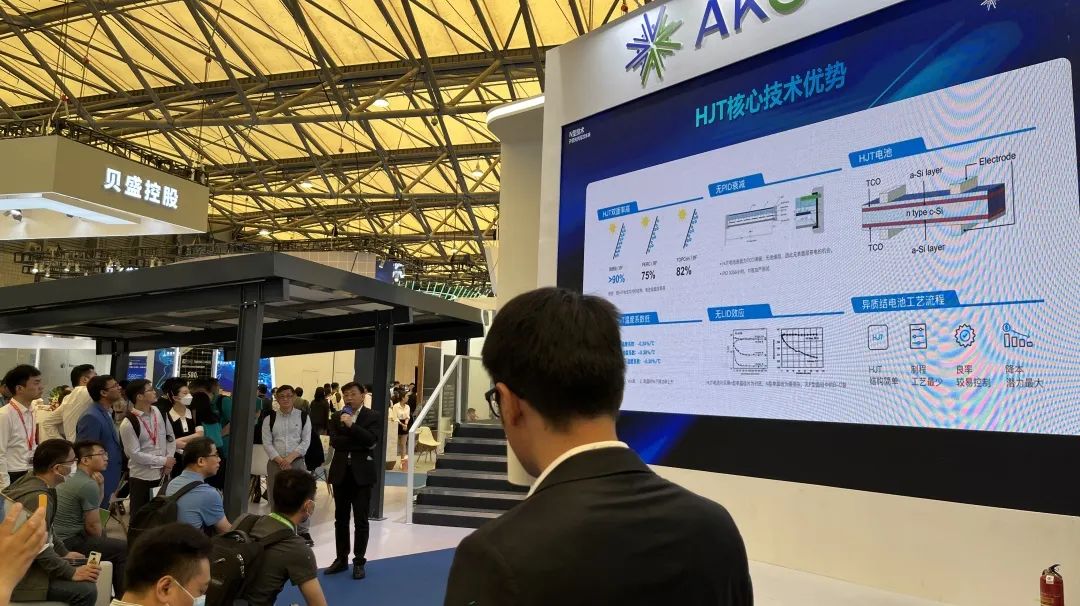

▲Akcome showcased at SNEC PV Power Expo

Akcome, one of the earliest leading businesses in China to deploy N-type technology, kicked off the research and development and production of HJT cell and modules since 2012, and is one of the earliest enterprises in China to be competent to produce HJT cells and modules in large quantities. Akcome considers technological innovation as the driver for corporate development, accumulated abundant HJT cell technology professionals, and is patented with over 100 patented technologies for HJT cell-related field. Akcome, after long-term cultivation and deposits, ranked the leading industry position for the research and development of key technologies, production capacity construction, cost reduction and efficiency improvement of HJT. At this exhibition, Akcome grandly launched AK iPower 7.0 Series HJT modules for centralized ground power stations. G12-66-720W multi-main grid HJT module, a high-energy optimization for large ground power stations, is equipped with 18BB super multi-busbar (SMBB), optical film transfer technology, dual-glass structure with butyl rubber sealing is feature with robust water resistance performance. Combined with excellent temperature coefficient (-0.24%/℃) and high high bifaciality(above 90%) , the conversion efficiency of the module can reach 23.2%, and the maximum power is up to 720W. The significant improvement in power generation performance throughout the entire lifecycle supports effectively reducing the electricity cost of the system and bring ing more investment returns to customers.

▲The Eye-catching Akcome 720W Multi-Main Grid HJT Module

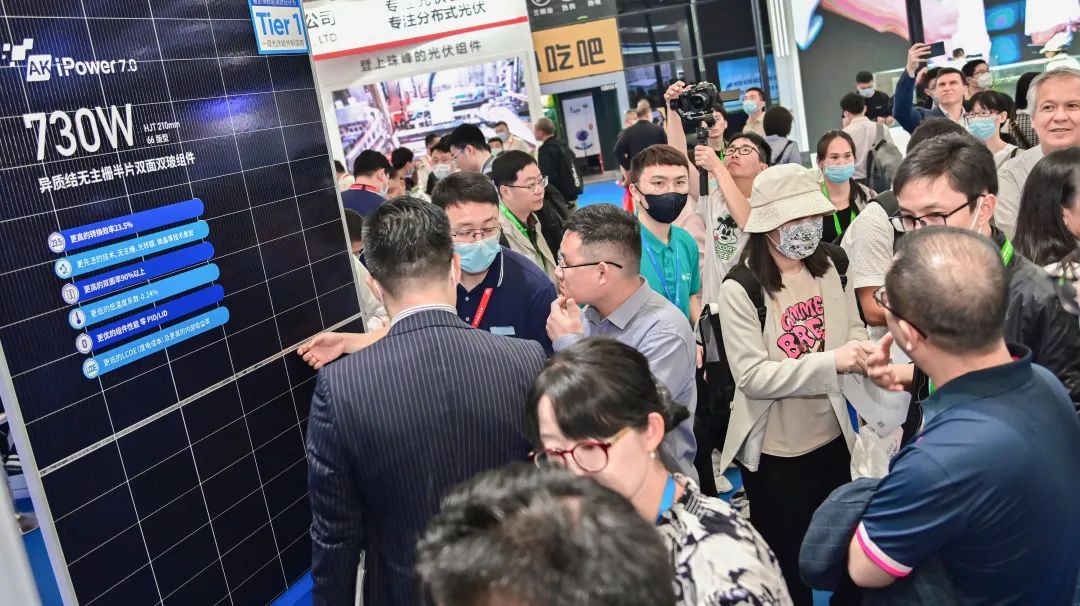

Another forward-looking module is Akcome's G12-66-730W heterojunction bificial double-glass busbar-free module. It adopts the 0BB (busbar-free) technology which breaks the routine, the shading area of grid lines on the surface of the cell is reduced, thus the series resistance can be effectively reduced, and the CTM of the module is increased by 1%. Superimposed with advanced technologies such as silicon-wafer thinning process, optical transfer film and microcrystal technology, the conversion efficiency is up to 23.5%, the bifaciality reaches 90%, and the maximum power reaches a breakthrough of 730W. It is a new power record of 720W created by Akcome and is in the leading position in the industry. This module has excellent power generation performance and has significant advantages in reducing BOS cost and LCOE.

▲ Akcome 730W bificial double-glass busbar-free module

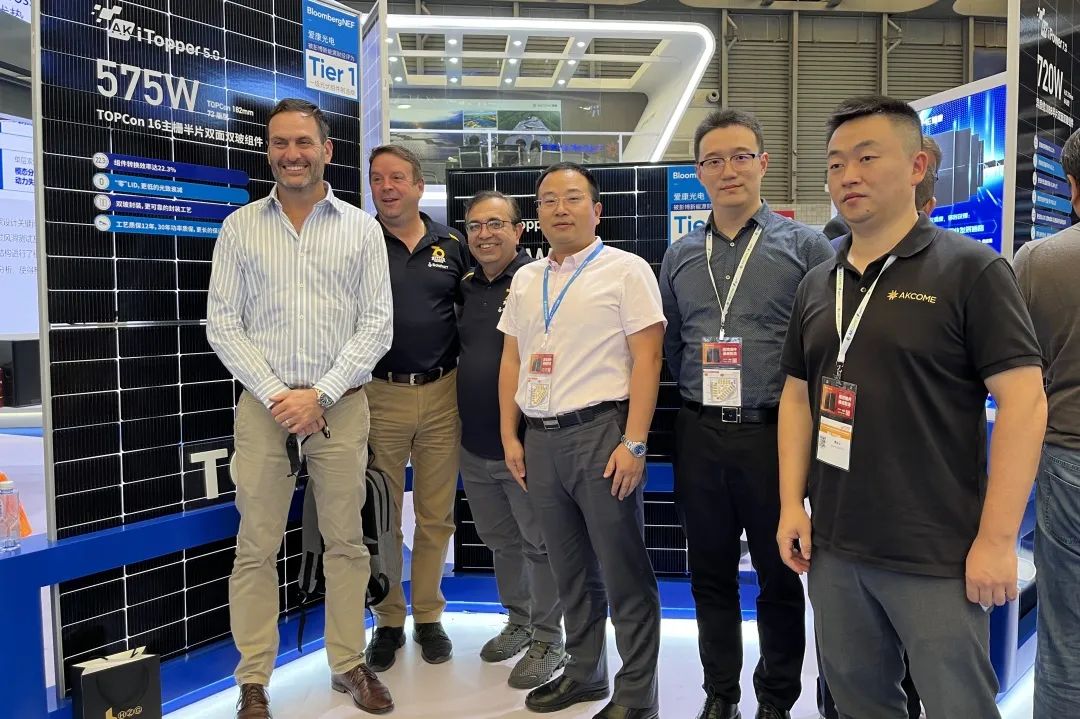

Akcome has initiated to synchronously lay out the TOPCon efficient modules production line with high market demand and industrial advantages in 2023 while actively implementing the industrial technology strategies focusing on HJT. To meet the differentiated requirements of global customers for different scenarios, Akcome showcased the AK iTopper series modules in three versions: 182-54 (435W), 182-72 (575W) and 182-78 (625W). AK iTopper series modules were widely used in centralized and distributed scenarios. Whether in industrial and commercial power stations, or residential power stations, AK iTopper Series modules were feasible to be designed with higher power, higher conversion efficiency and optimal size, thereby providing customers with lower energy costs and long-term reliable power generation guarantees. Especially 182-54 (435W) modules of the AK iTopper 4.0 series, have gained the favor of massive overseas users by feat of their fully ultramodern high-quality appearance and lightweight and portable size.

▲Zhang jinjian, COO of Akcome Technology, is introducing AK iTopper series modules to overseas clients

In addition to focusing on the development and upgrading of new and efficient modules, Akcome is also committed to the "cost reduction and efficiency improvement" of high-efficiency photovoltaic cells and modules. The progress of cost reduction and efficiency improvement in Akcome HJT is continuously advancing. For silicon materials and wafer processing, Akcome implemented wafer thinning technology research and testing with respect to HJT silicon wafers based on the bificial symmetrical structure and low-temperature process strengths of HJT cells. At the end of 2022, Akcome introduced the 120um HJT silicon wafers for mass production, reducing the cost of 0.6 to 0.7 Yuan per 210 half-wafers approximately. Compared to the 150um-thick cell, the efficiency of the 120um thick cell increased over 0.2%. Presently, Akcome is conducting mass production testing of the 110um silicon wafers, with the aim of introducing the 100um-silicon wafers for mass production by the end of 2023. For the optimization of the HJT film structure, Akcome is fully implementing investigation on the application of nano-crystalline silicon manufacturing technology, the introduction and structural optimization of microcrystalline processes, and application of metal oxides. Presently, the average efficiency of single-sided microcrystalline HJT cell production line from Akcome came up to as high as 25.4%, and that of the bificial microcrystalline HJT cell is up to 25.7%.

▲ Keynote speech on Akcome N-type technology

For the cost reduction of silver paste, Akcome mainly focused on the research and development of busbar line optimization and busbar-free technology, as well as the application testing of silver-coated copper materials. For the cost reduction of TCO, Akcome is facilitating the development of new high-mobility TCO and indium reduction and indium-free coating solutions, thereby promoting cost reduction and efficiency improvement of HJT cell and modules. For TOPCon technology, Akcome mainly optimizes material costs through technologies involving silicon wafer thinning, SMBB, and laser transfer print, and improves product efficiency and reliability by optimizing metal composite and metal contact process.

The exhibition is fully successfully held. With continuous research and development innovation, reliable production and quality, and excellent customer service, Akcome has gained the trust and support of countless newly contacted and regular customers. Facing the rapid growth and transformation and upgrading trend of the N-type market in the future, Akcome will focus on efficient photovoltaic technology innovation, explore the unlimited possibilities of N-type product application, and embrace partners to build a photovoltaic value synergy, promoting high-quality development of the photovoltaic industry.

Sprechzeiten: 8:00-17:00 Uhr an Wochentagen

HQ: 0571-89089399

Sales: +86-512 8255 7328

Mail: modulesales@akcome.com

Hauptsitz: Raum 901, Gebäude 1, Nr. 1818-2, Wenyi West Road, Yuhang Street, Bezirk Yuhang, Stadt Hangzhou, Provinz Zhejiang